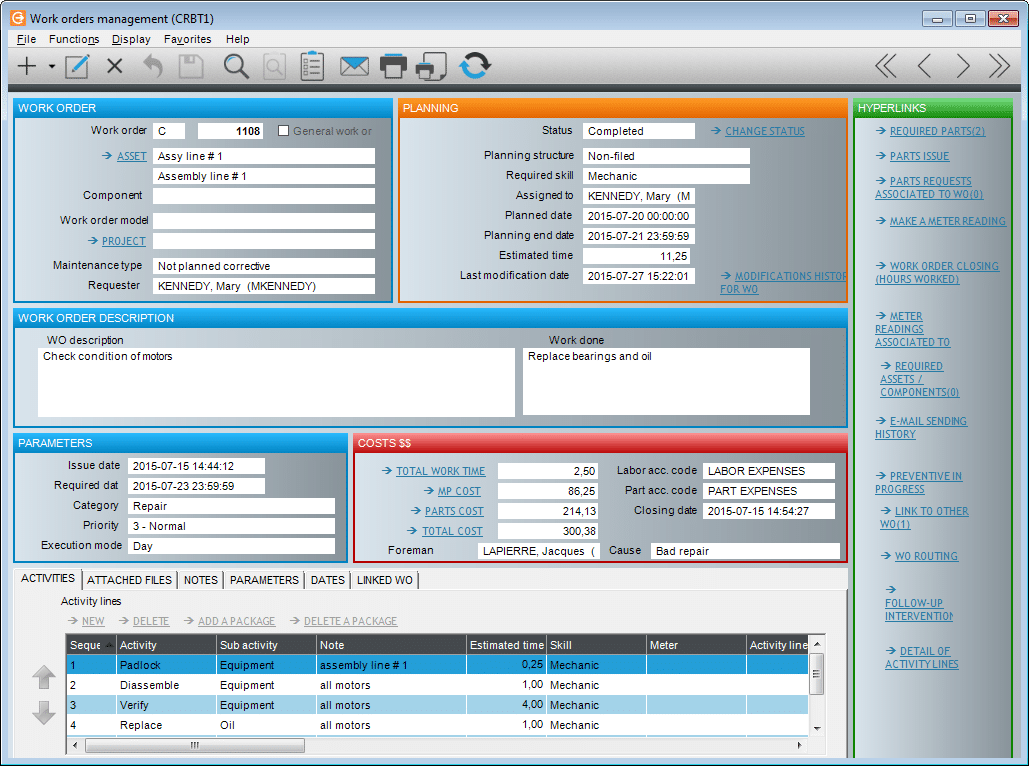

Create and manage effectively corrective and preventive tasks with Guide Ti’s work orders advanced tool.

Efficiently manage planned PM work orders, emergencies, and maintenance projects with Guide Ti’s work orders management module.

Guide TI offers not only work order management, but also the management of corrective and preventive interventions and detailed business processes.

With Guide TI’s work order management module, you have complete control over your maintenance activities. You can track emergencies and machine stoppages in real-time and, above all, reduce downtime! This will reduce your maintenance costs while making your processes more reliable and faster.

No other maintenance software or work order management system makes it so easy to create, edit, and close work orders. Guide Ti’s innovations and advanced functionality create a positive impact on operations. The power and management capacity of work orders in Guide Ti is one of the differentiating elements of our CMMS compared to other solutions on the market.

Here are some features:

- Work orders regroup all details for repair.

- Access to historical repairs on assets.

- Access spec sheets.

- Bill of Material.

- Templates

- Better track your maintenance tasks with the many fields available in the work order.

- Customizing the input form is easy to set up and saves a lot of time.

- Customize the form for each department and each user profile.

- In addition to describing the task to be performed and information about the assets involved, Guide Ti lets you categorize your WOs for easy sorting, analysis, reporting, and performance indicators.

- Use alarm management and notification tools to make your processes faster and more robust and reliable.

- The work order entry form is customizable for each department and user profile.

- Create emergency repairs from your monitoring tools and our web service.

- Create service requests through our Guide Ti web application (HTML5); configure the fields to use, the required fields, the order of entry, etc.

- Optimize user experience with drop-down menus, checkboxes, multiple selections, and dates available in a calendar.

- Review and quickly select equipment

- Use templates to facilitate registration of emergencies and guide the user.

- Calculate priority according to different parameters, such as criticality of the equipment and level of risk (environment, safety, machine stoppage, evaluation of the applicant, etc.).

- Automate shipments via notification or alarms to the troubleshooting team.

- Supervisor alarm if an urgent request does not get a response after the time limit you have set.

- Automatic update of the emergency table as soon as the task is taken care of.

- Timestamp.

- Calculation of machine downtime.

- Real-time indicator function of equipment currently under repair.

- When the work order closes, Guide Ti displays stop time by a simple classification allowing a quick analysis of trends.

- Automated countermeasure processing generation (reliability) for machine shutdowns longer than a set time limit.

- Monitoring countermeasure elements.

- Transfer of uncompleted work to the next shift.

- Preparation of meetings for shift change.

11 business challenges that CMMS Guide Ti can help you meet

Guide Ti is a maintenance management tool that has an impact on all of a company’s operations.

In fact, implementing good maintenance practices combined with the use of Guide Ti will help your organization be more competitive.

With Guide Ti, COGEP helps companies meet 11 challenges they face in their quest for excellence.